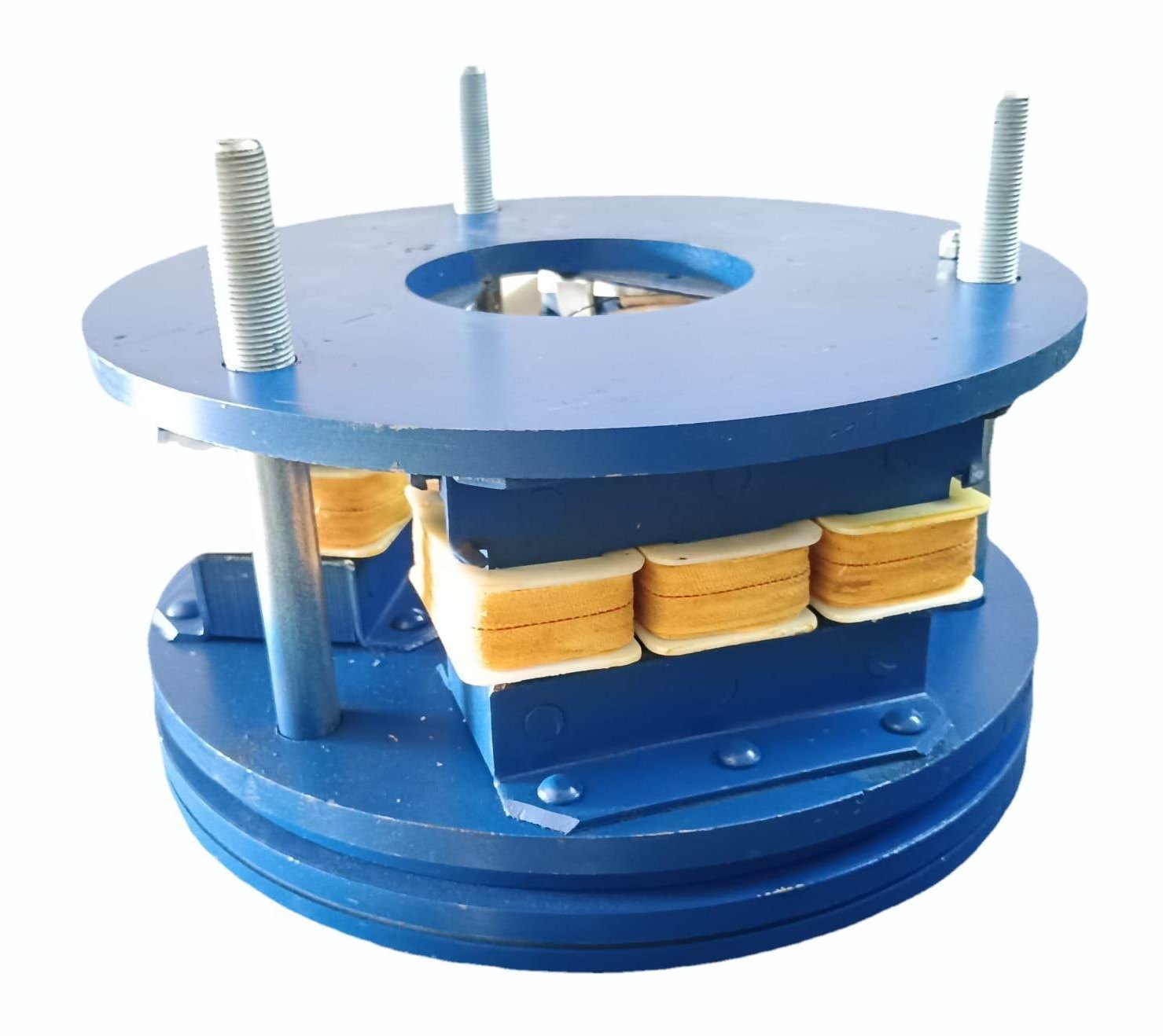

Electromagnetic Brake Coil Repair

At Shivam Electrical, we specialize in electromagnetic brake coil repair and rewinding services for industrial and commercial equipment. Our skilled technicians handle all types of electromagnetic brake coils, ensuring precise restoration, reliable operation, and long-lasting performance. We provide comprehensive fault diagnosis, coil rewinding, insulation testing, contact cleaning, and replacement of worn components, restoring your electromagnetic brake systems to optimal working condition. Every repair is carried out with attention to detail, using high-quality materials and following industry best practices to ensure safety, efficiency, and durability.

We understand that downtime of electromagnetic brake systems can significantly disrupt operations, which is why our team works to quickly diagnose, repair, and optimize your coils. Our solutions are designed to be cost-effective, long-lasting, and customized to the specific requirements of each system. From initial inspection to final performance testing, we ensure your electromagnetic brakes operate smoothly, reliably, and safely, providing precise braking performance for your machinery.

At the same time, our approach goes beyond just repairing faults — we also enhance the overall efficiency and performance of your electromagnetic brake systems. Through careful inspection, precision rewinding, calibration, and testing, we minimize wear, improve response time, reduce energy loss, and extend operational life. This dedication to reliability, safety, and performance makes Shivam Electrical the trusted choice for businesses that require high-performing electromagnetic brake coil solutions.

Our Work Process

Our electromagnetic brake coil repair workflow is designed to deliver consistent, high-quality results and optimal system performance:

- Inspection & Testing: Detailed examination of all coil components to identify faults.

- Fault Diagnosis: Detect issues in windings, insulation, and contact points.

- Precision Repair & Rewinding: Repair or replace damaged components and rewind coils accurately.

- Calibration & Alignment: Adjust coil positioning and alignment for precise braking response.

- Quality Checks: Perform thorough inspections to verify efficiency, safety, and durability.

- Final Performance Testing: Test coils under operational conditions to ensure proper braking performance.

This structured workflow ensures minimal downtime, improved efficiency, and long-lasting performance for all electromagnetic brake systems.

Service Features

Our electromagnetic brake coil repair services cover a complete range of solutions, including coil rewinding, fault diagnosis, insulation testing, contact cleaning, component replacement, calibration, preventive maintenance, and performance optimization. We also focus on energy efficiency improvements and extending the operational life of your brake coils. Every service is reliable, cost-effective, and tailored to meet your operational requirements, ensuring smooth, safe, and efficient performance for your machinery.